Schedule Risk Analysis Framework

Know What to Expect

Know What to Expect

- Documentation Required

- Key Participants

- Software Utilized

- Timeline

- Workshop Process

- Deliverable Reporting

We are happy to announce our next online module, Basic Turnaround Cost | 3315.

Following the Intro to Cost, this Basic Turnaround Cost training course is designed for individuals that do not have any turnaround Cost Management experience. This course will give you a basic understanding of the Cost Professional’s roles and responsibilities during a Turnaround. This course will be a hybrid of lectures and hands-on activities.

You always have full access to the Project Controls University course material. Plus, the course now includes 1-week access to our Custom Training Environment. This training environment gives you the opportunity to complete all lesson exercises directly from your browser. Microsoft Excel files needed for exercises in this class are provided in the custom training environment.

We recommend having an additional screen available to easily change views between the two browsers. Easily view your lessons and complete each exercise side by side.

Please contact us at training@tepco.us for any questions you may have.

WorkPAK can easily be implemented across all industries and sites involving Project Management. The dedicated software team behind this powerful platform spent nearly 11 years perfecting its design; paying meticulous attention to detail and developing the application to include requested content and performance capabilities from clients and other Project Controls professionals, all of whom the application is intended for use by (i.e. planners, schedulers, cost professionals, plant managers, materials, logistics, documents controls, maintenance, engineering, etc.).

With our customer-focused approach to design, along with the invaluable feedback we received during select site beta-testing, WorkPAK is currently in successful operation throughout several industries and sites and comes highly recommended by those using the application. The application started off as an access database, but the need to have many users in a single program, without slowing anything down, quickly led us to switch to a .net application. During the development of WorkPAK, we found that a lot of things were hardcoded, so over the last 5 years, our IT has been working on making it more customizable. Instead of being a one-size-fits-all program, sites are able to customize WorkPAK, which enables them to utilize the tool for turnarounds, capital projects, and really any industry out there. We made it where it is robust and flexible enough to fit any industry.

WorkPAK is unique in the sense that it integrates Planning, Cost, and Scheduling within the same program. By combining multiple areas of work within the same database, WorkPAK offers a level of transparency that has been lacking in the Project Controls industry.

WorkPAK combines planning and cost, but also houses inspections, procurement,

safety, maintenance, and much more. While having people from different fields working in the same database is nice for keeping things organized, and consistent, we did recognize the need to implement security measures, so we developed the system permissions. With the creation of the system permissions, users are assigned either edit or view rights, depending on what they need to access the program. For example, a planner will be given edit rights to plan jobs, but will not need to see the Cost portion in WorkPAK. Their permissions would be assigned accordingly, so when the planner logs on, all they would see is their planning portion. For a manager that may need to see everything in WorkPAK, they could be given view permissions, allowing them access to see planning, cost, reports, and everything happening within WorkPAK.

One of the ways WorkPAK brings together Cost and Planning is by building the 10%

estimate simultaneously. Rates are first assigned to items such as tools, crafts, materials, and more at the system, or global level during implementation. These rates can then be edited at the event level to keep up with price changes. By setting up these rates, as the planners are planning, and adding in these items, WorkPAK is also building the 10% estimate in the background. This allows sites to arrive at their 10% estimate earlier, and without having to seek outbids.

It’s easier than ever to reference older plans and cost information with WorkPAK’s ability to warehouse historical data. Once complete, plans can easily be hidden from view to keep the interface from getting too busy. If there’s something that needs to be referenced down the road, all it takes is the click of a button to see all the event details again. Building on this, WorkPAK also allows the cloning of jobs or even entire events. Instead of having to plan the same turnaround over and over, the entire event can be cloned, then adjusted as needed.

WorkPAK allows P6 mapping to make it quicker, and easier to get activities into the schedule. A P6 template is imported into WorkPAK, the corresponding fields between the two programs are then mapped and stitched together, then saved within WorkPAK. Once exported from WorkPAK, the jobs are in an excel spreadsheet already formatted to import to P6 without any data cleanup or manipulation.

We understand that every site is unique,

and a one size fits all software can be challenging to work around. That’s why we developed the Custom Fields option in WorkPAK that allows you to add in any site-specific item you may need.

One of the greatest compliments we get from clients utilizing WorkPAK is the quick response we provide to any issues or questions they may have. The software developers, as well as the help desk team, are in-house, and place the utmost importance on helping our clients with anything they need. Other applications out there require you to submit a ticket, which may take them days, or even weeks to get to. Our team responds in minutes.

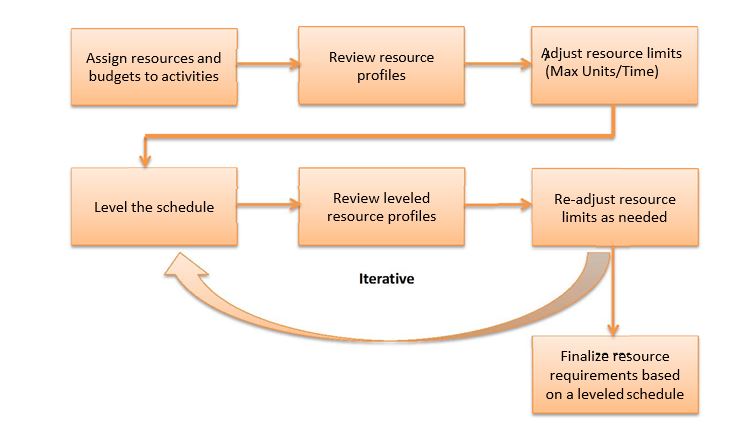

A major part of turnaround and project scheduling is understanding resource requirements and resource availability.

• Understanding resource limits is necessary for P6 leveling.

Here is a basic process flow:

When you level a project in P6, activities are moved to the right on the Gantt chart in an attempt to remove over-allocation.

Prior to using the leveling functionality in P6, consider the following:

NOTE! Leveling is not rocket science. Many P6 users try to use the leveling functionality to draw a very detailed picture that they want to see. P6 runs numerous algorithms during leveling at a complexity that few people could easily understand.

Some tend to over-use leveling priority codes or level only specific resources. Keep it simple and do not overcomplicate it. Leveling should only come after a well built and scheduled plan has been developed. It should be applied towards the end of the planning phase. Good leveling relies on activity attributes, including priority coding, resource assignments and limits, logic, constraints, and float. Ensure all of these attributes are in place prior to leveling.

There are two primary approaches to resource-leveling:

Pre-defined Start and Finish (Most Common):

Scope and Resource Availability Determines Duration:

Pre-Defined Start and Finish: Work must be completed within the duration.

Pre-Defined Resources: Work must be completed with the number of resources.

Duration is not of concern.

In this example, the hard finish constraint is removed. P6 is allowed to level past the finish milestone, resulting in a longer duration, but no over-allocation.

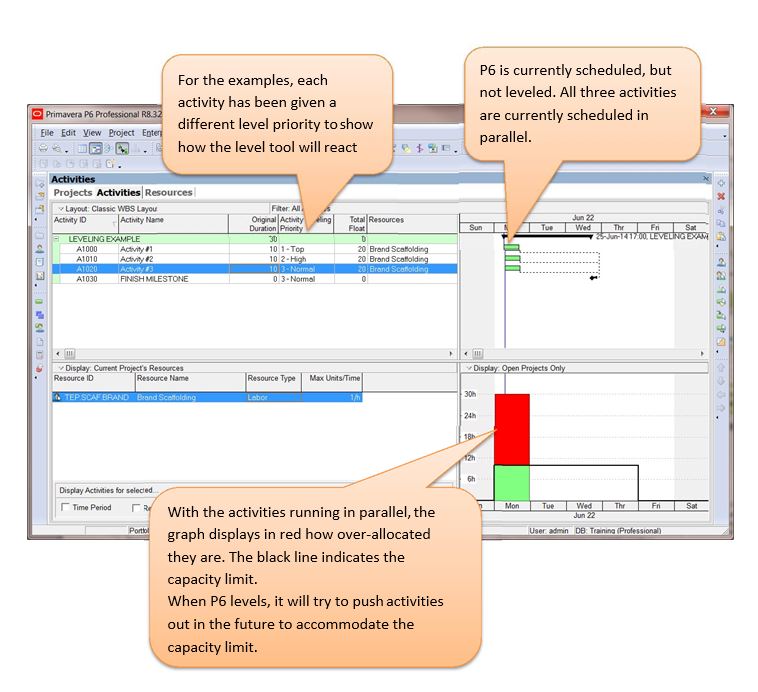

P6 Basic Leveling Examples:

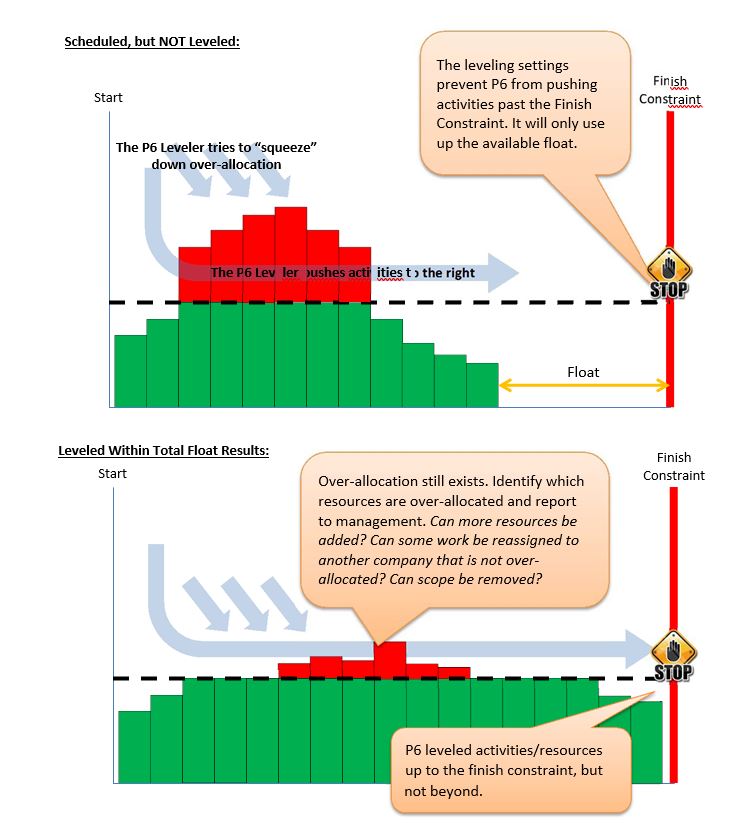

The following examples explain how the P6 leveler will react based on how the option Level Resources Only Within Activity Total Float is set in the P6 leveling options.

The examples are based on three activities, each set with the Activity Leveling Priority 1, 2, and 3 respectively. The fourth activity is a finish milestone that all three activities are linked to, which will used be to describe the difference between leveling within float vs. leveling without float.

Example #1 – Scheduled, but Not Leveled:

This example contains three activities with 10 hours duration each on a 4×10 calendar, each linked to a finish milestone. The finish milestone has a Finish On constraint set to the end of the third day.

The activities are not linked to each other.

A scaffold resource is assigned to each task as a single headcount. Since the three tasks are scheduled to work at the same time, the graph in the lower right indicates that we need three Brand Scaffold resources during the first day to complete the work.

Our limit line in the graph indicates that we only have one Brand Scaffold resource available. The red on the bar indicates our over-allocation.

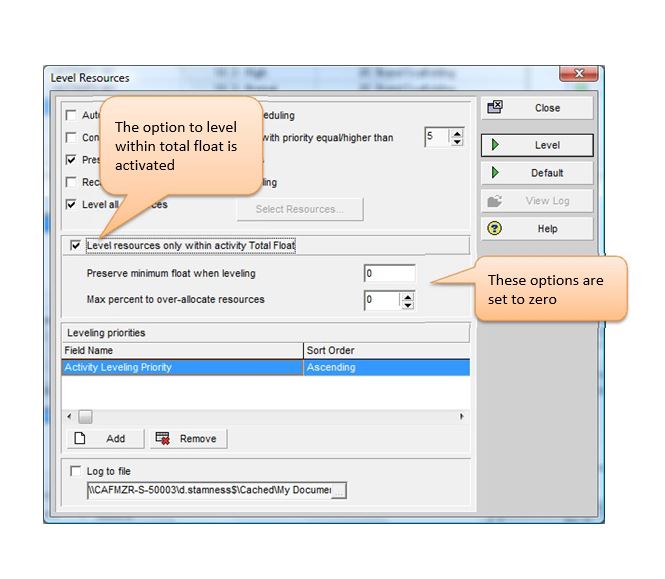

Example #2 – Leveled within Total Float:

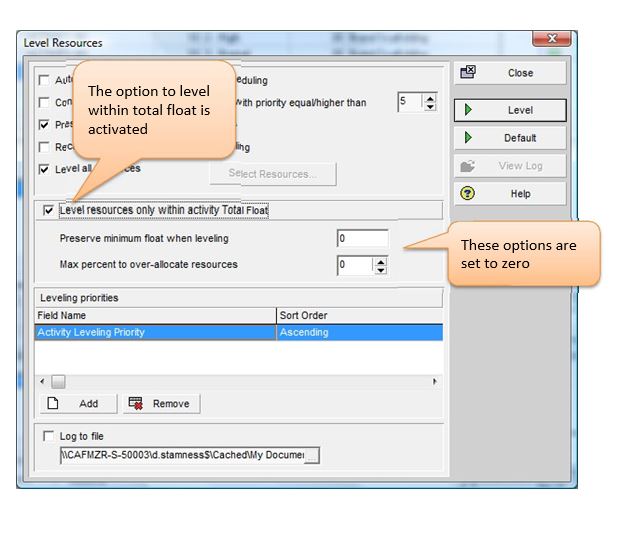

The option Level Resources Only Within Activity Total Float is selected, with both the preserve minimum float and max percent to over-allocate set to zero.

Go to the Level Resources window by pressing Shift+F9 on your keyboard, or click the Level

Resources button in the toolbar.

Example #2 (cont.) – Leveled within Total Float:

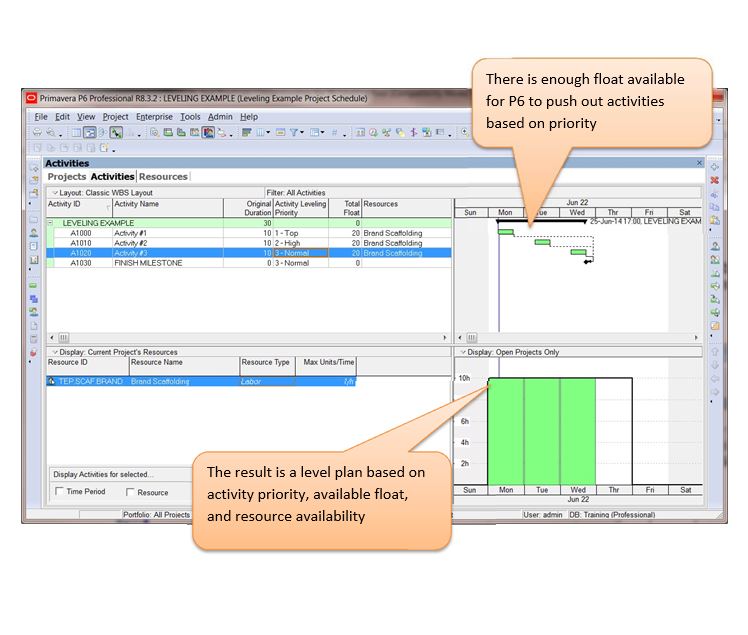

This example has been P6 leveled. There was enough float available to level all three tasks based on their Activity Leveling Priorities. Activities #2 and #3 leveled out based on their priority assignments.

Now P6 shows that the single resource can achieve the work over the next three days.

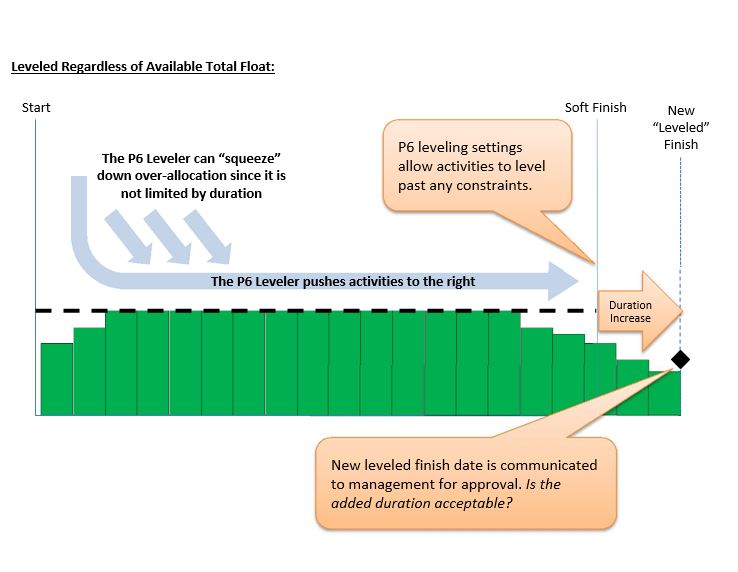

Example #3 – Leveled regardless of Total Float, but with an earlier constraint date on the Finish Milestone:

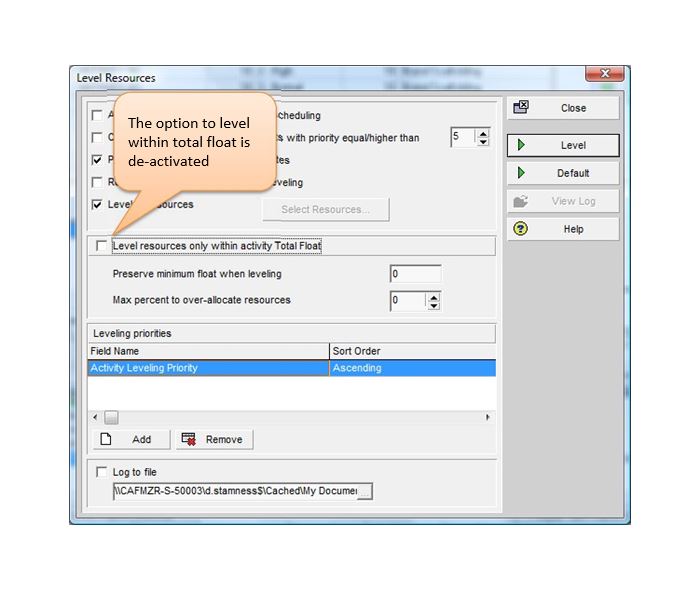

The option Level Resources Only Within Activity Total Float is de-selected.

Also, the milestone has a finish constraint imposed on it indicating all tasks must be complete by

the end of the second day.

Example #3 (cont.) – Leveled regardless of Total Float, but with an earlier constraint date on the Finish Milestone:

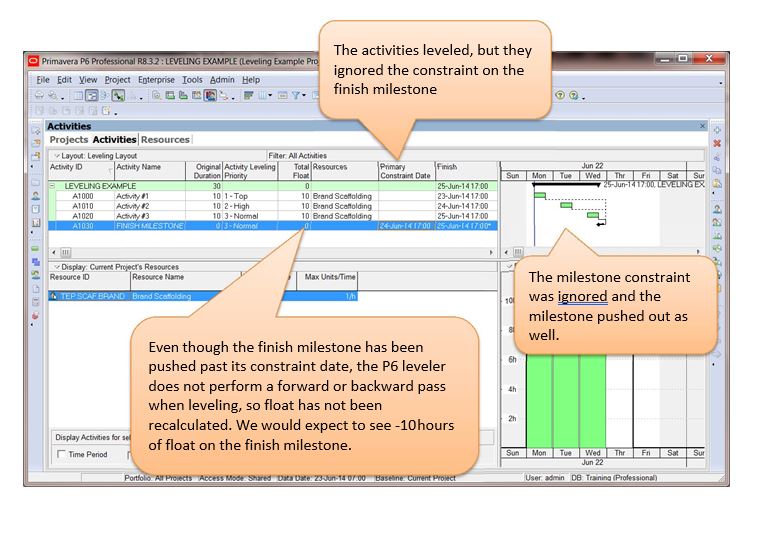

This example has been P6 leveled. Since we de-selected the option to level within total float, P6 ignores the fact that there is a constraint on the finish milestone, so it leveled the tasks and pushed the milestone.

Activities #2 and #3 are again leveled out based on their priority assignments.

The P6 leveler also pushed out the finish milestone, even though it is assigned a Finish On constraint set to the end of the second day.

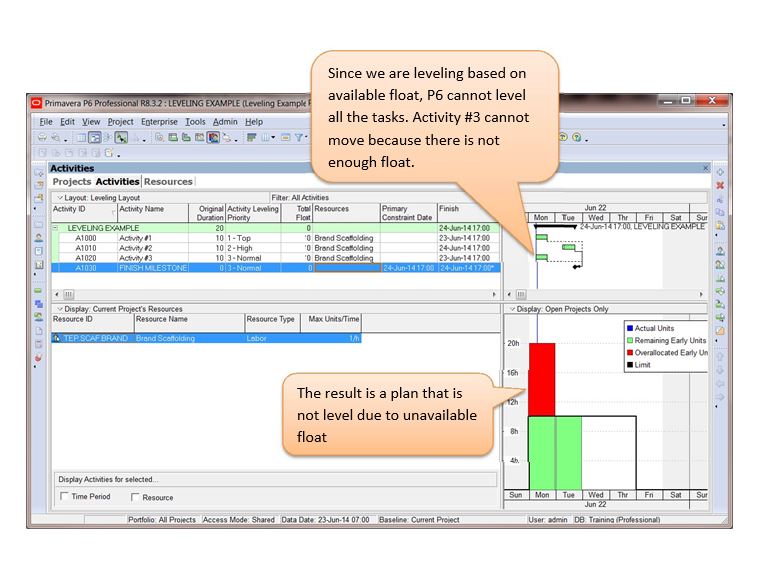

Example #4 – Leveled within Total Float, but with an earlier constraint on the Finish Milestone:

The option Level Resources Only Within Activity Total Float is selected, with both the preserve minimum float and max percent to over-allocate set to zero.

However, the milestone still has a finish constraint imposed on it indicating all tasks must be complete by the end of the second day.

Example #4 (cont.) – Leveled within Total Float, but with an earlier constraint on the Finish Milestone:

This example has been P6 leveled. The schedule does not contain enough float to level out all three tasks.

P6 determined (based on the activity leveling priority) that Activity #2 can push out, but there is not enough float available to push out Activity #3.

So Activity #3 remains scheduled on Monday, leaving the resource over-allocated.

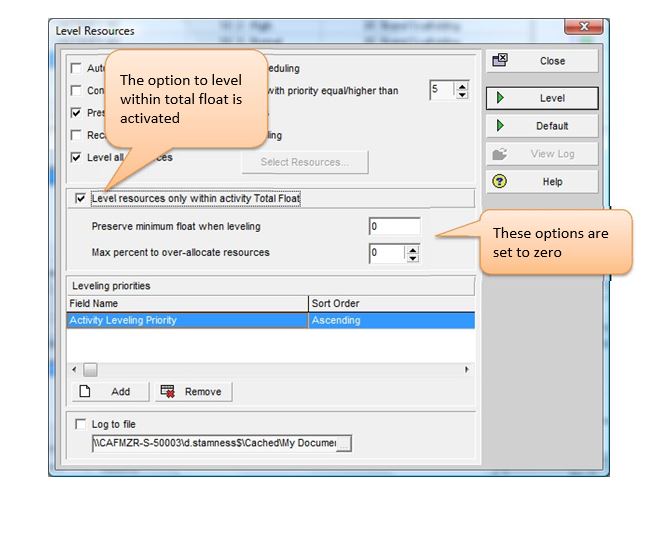

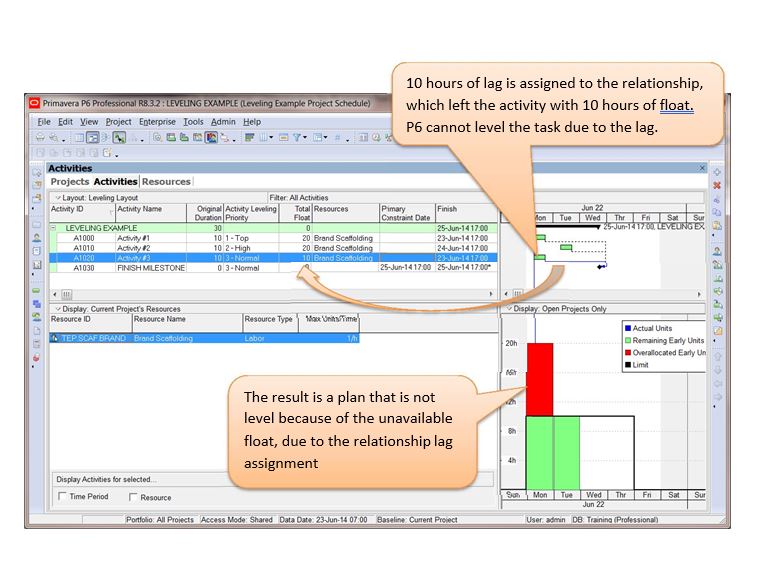

Example #5 – Leveled within Total Float, finish milestone reset to day 3, but lag imposed:

The option Level Resources Only Within Activity Total Float is selected, with both the preserve minimum float and max percent to over-allocate set to zero.

Example #5 (cont.) – Leveled within Total Float, finish milestone reset to day 3, but lag imposed:

This example has been P6 leveled. Since the milestone constraint has been reset to the end of the 3rd day, there should be enough float to level the tasks just like Example #2 above. However, in this example we have imposed relationship lag between Activity #3 and the Finish Milestone.

Lag is considered NON-WORK time. It is not float. Since lag was imposed on the relationship link between Activity #3 and the Finish Milestone, Activity #3 will not level out. Activity #3’s available float has been reduced due to the lag that was imposed.

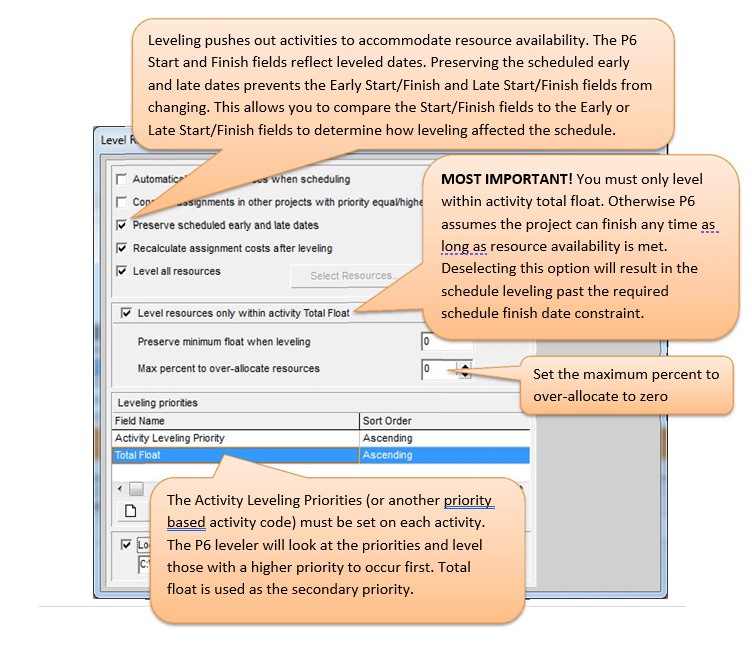

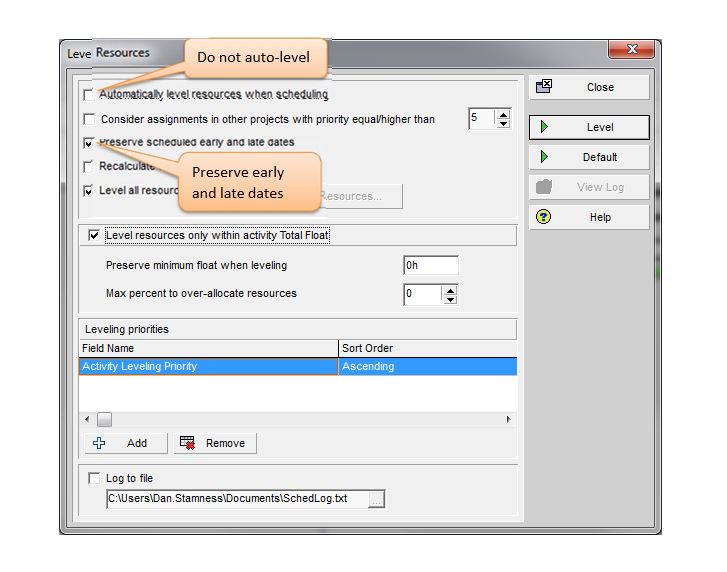

P6 Leveling Settings

Prior to leveling any project in P6, the leveling settings must be configured. Settings are saved with each individual project, so they must be set up for each P6 project the scheduler works with.

To view and modify the P6 leveling settings:

Level Resources Dialog Box Definitions:

Leveling Priorities:

Now that we have discussed the different leveling options, here is an example of what you may typically use for turnaround and project leveling:

Leveling All Resources VS. Leveling Selected Resources

The leveling window has an option to level all resources, or you can select to level specific resources. Some schedulers insist on selecting only those resources that they want to level.

Before you make this choice, ask yourself what the benefit is in selecting specific resources versus leveling them all. What does it buy you? In most cases, there is no harm in leveling all resources, even if you have an abundance of a particular craft on hand. Leveling all resources will provide a more gradual S-Curve Planned Value in the baseline. Just because a plan is leveled does not mean that you can’t aggressively work activities sooner than the leveled dates, if you have the capability to do so.

So don’t be afraid to level them all. If the planned value (baseline hours) in the S-Curve is fully leveled, you will find that setting and meeting upper-level management expectations of planned hours per day (SPI) is much easier to manage.

Activity Leveling Priorities

P6 contains a built-in code field called Activity Leveling Priority. By default, all activities are assigned the value 3 – Normal. If you intend on using the leveling functionality in P6 for the TAR, and intend on using the built-in Activity Leveling Priority code values, these value must be set on each activity.

There are five activity leveling priorities in P6:

1 – Top

2 – High

3 – Normal

4 – Low

5 – Lowest

You are not limited to using the Activity Leveling Priority field in P6 for leveling. If you have priority standards in your organization that require more than the five code values, you can create them as an activity code and then use the activity code for leveling priorities.

Define your priorities! Your organization should define what each priority means. Typically high- risk equipment with unknown inspection results or historical data showing a low level of confidence in the equipment will get coded with “1 – TOP”. This would also include all critical path jobs.

Secondary risk and near critical jobs should get coded as “2 – HIGH”, and so on. Only extremely low risk work with a high amount of float will get assigned the low or lowest values.

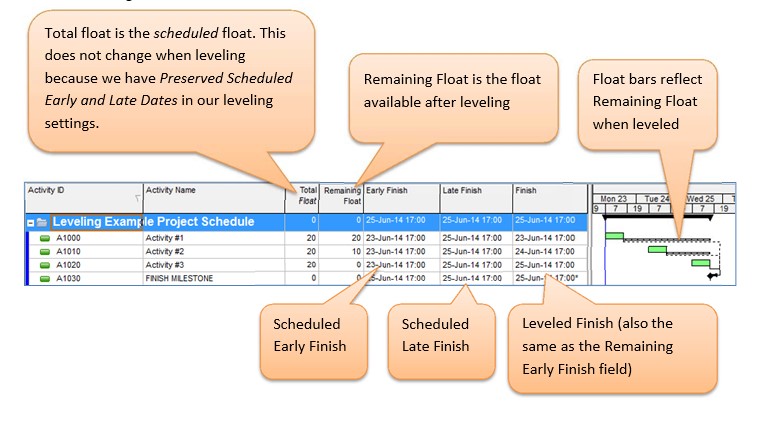

Float Analysis When Leveling

It is recommended that you do not perform float analysis on a leveled schedule. With this in mind, it is also recommended that you do not set P6 to automatically level when scheduling. Keep the two functions separate. HINT: Press F9 to schedule, and then press SHIFT-F9 to level.

It is also recommended that you apply the leveling setting “Preserve Schedule Early and Late Dates”. This will ensure that the early and late date fields are reflecting the Scheduled dates, not the Leveled dates.

The Start date and Finish date fields in P6 will show the leveled dates.

Total Float and Remaining Float

P6 provides an additional float field called Remaining Float. You can analyze float using this field when a project is leveled.

NOTE: Remaining Float equals the Total Float when the schedule is NOT leveled.

So if you review the two columns side-by-side, the Total Float is the Scheduled float, and the Remaining Float is the Leveled float.

Cross-Linking Jobs or Equipment

Many schedulers tend to link from one job to another in order to push jobs out for the sake of leveling. (For example, tying piping Job A, to Job B, to Job C, and so on…) The problem is that the jobs have absolutely no relationship to each other. “Chaining” jobs together for this purpose is not a good practice, although there could be exceptions depending on the situation.

Also, when linking jobs together in this manner, float is reduced for each job. The more that are chained together, the more the float is reduced. Eventually, the combination of a bunch of small jobs linked together could turn into the primary critical path.

Cross-linking jobs should only be done when it logistically makes sense, not for the sake of leveling manpower. Doing so only prevents the P6 leveler from functioning properly.

An example of when you might cross-link jobs is when you must remove Exchanger A before you can get at Exchanger B. Exchanger A must be out of the way first. Another example is when you have valves on a column. If the column must be decommissioned, opened, cleaned, and approved for entry before working on the valves, then it’s a good idea to link the start of the valve work to the entry activity of the column.

Using Secondary Leveling Priority Codes

As another example, let’s say you have five columns that are all considered a high priority. They are all independent of each other, so there is not any cross-linking between them. Although they are all considered a high priority, one is high risk for discovery work. In this situation you may want to set up a secondary priority code for equipment. You could create an activity code called Equipment Leveling Priority and assign that priority code for secondary leveling criteria.

Changing Leveling Priorities During Execution

You can change your leveling priorities during execution. Using the previous five columns as an example, let’s say the first column is inspected and it’s discovered that no repairs are required. It might be best to change the remaining activities for the first column to a lower leveling priority, releasing the manpower urgency to the other four columns.

System Leveling Priorities

For turnaround scheduling, as equipment inspection starts to get near completion, you could change your leveling priorities to be based on system turnover priority. Operations have most likely identified the priority of the systems and when they would like them returned. You could set up another activity code called System Turnover Leveling Priority. Once you are to the point in execution where the team is nearing the turnover of equipment back to operations, the leveling parameters can be changed to level based on System Turnover Leveling Priority.

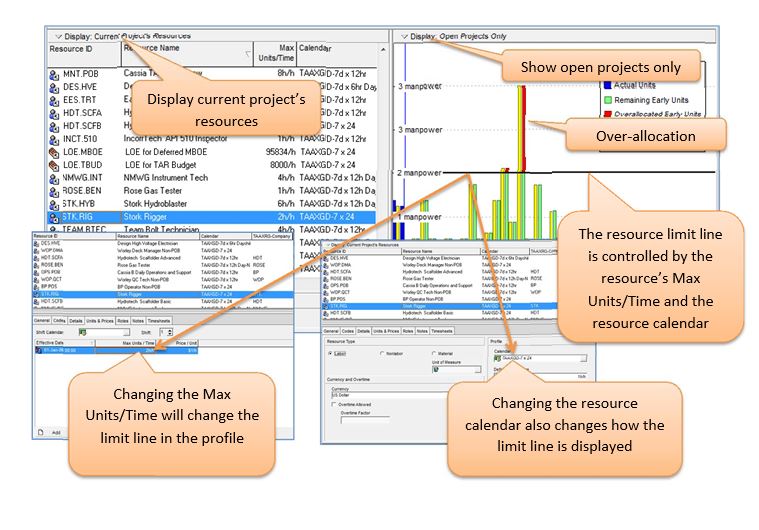

Setting the Resource Limits (Max Units/Time)

Resource allocation analysis must be conducted throughout the planning and scheduling process. Understanding resource limits is necessary for resource management and P6 leveling.

Each resource in P6 contains a Max Units/Time field to impose a limit line when viewing resource profile views.

Although activities should be configured as Task Dependent to ensure the activity calendar is used during scheduling, the Resource Calendar may need to be modified as well, as it also affects how the resource limit lines are displayed in a resource profile.

Adjusting Resource Max Units/Time is an iterative process. You will most likely review a specific resource profile allocation while jumping back and forth to the resource breakdown structure until the Max Units/Time have been sufficiently adjusted to accommodate resource limitations and P6 leveling.

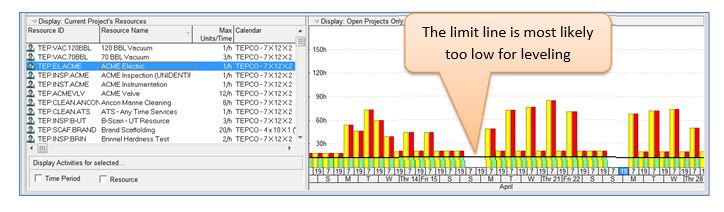

Resource Max Units/Time (Limit) Line Example:

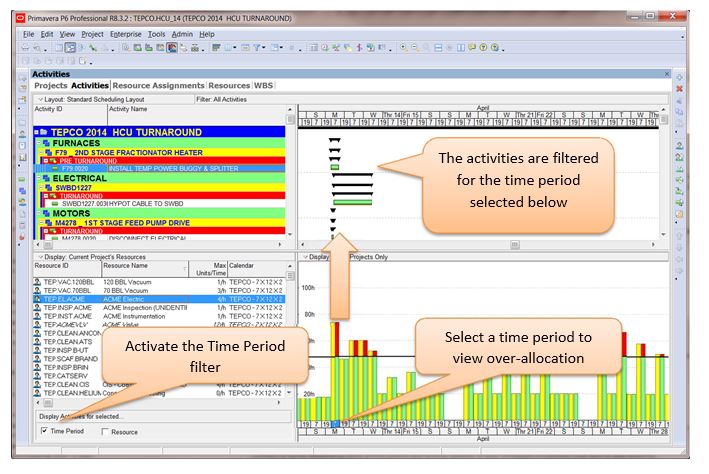

Steps for Adjusting the Resource Limit Line

1) Select the Resource Usage Profile button.

2) In the lower left pane, select the Display drop-down and ensure the view is filtered to display Current Project’s Resources.

3) In the lower right pane, select the Display drop-down and ensure Show All Projects is NOT selected.

4) Schedule (F9) the project.

5) Select a resource in the lower left pane and review their profile in the right pane. Adjust your timescale as needed to show the profile. Notice how the limit line is too low to accommodate the amount of work in this example.

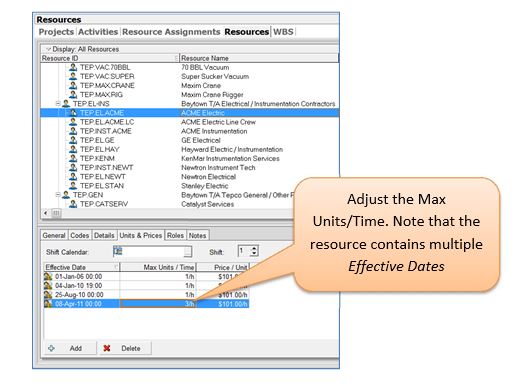

6) Go to the Resources view and select the resource.

7) Adjust the Resource Max Units/Time under the Units & Prices tab

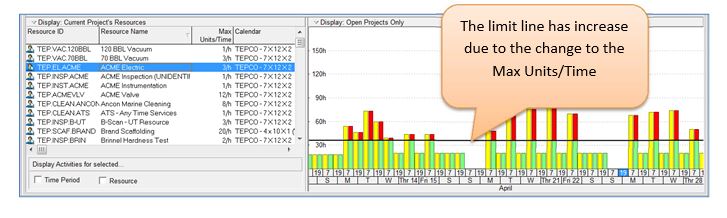

8) Return to the Activities view and look at the resource profile again. The limit line has now increased.

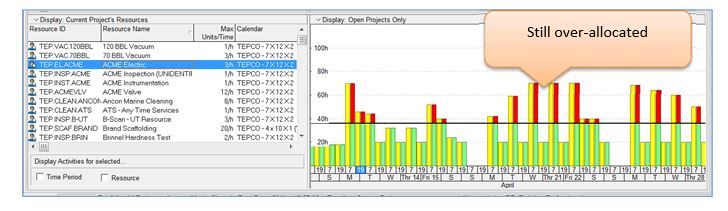

9) Level the project to see the results of leveling the resource. Notice that the resource is still over-allocated.

10) Return to the Resources view and set the Max Units/Time for the resource a little higher.

11) Return to the activities view, level again, and review the profile.

12) If your top activities table is collapsed, right-click and select Expand All

13) In the lower left pane, turn on the filter option checkbox for Time Period.

14) In the resource profile, click on the time periods in the timescale that are over-allocated. The activities table at the top will filter to show the activities that are part of the over- allocation.

Continue the same procedure for all the other resources. Continue to re-schedule and re-level as you go through the iterations.

Keep the following in mind:

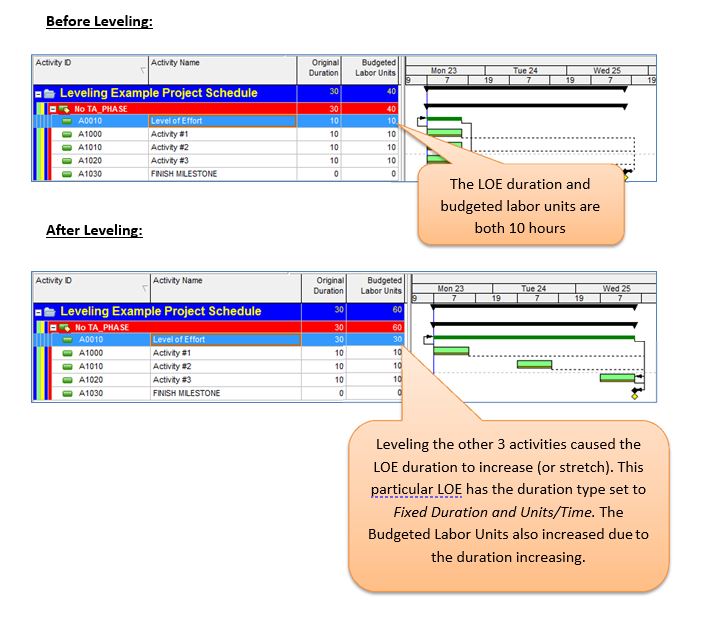

Level of Effort Calculations When Leveling

Although LOEs are not included in the resource profile analysis when leveling, when an LOE activity is linked to other activities, the LOE duration can increase when the other activities are leveled. Depending on your Duration Type assigned to the LOE, the total resource hours on the LOE can increase when the duration increases due to leveling.

In the following example, the LOE is linked to Activity #1 and Activity #3. Note the difference in the Budgeted Labor Units field before and after leveling. Note: the resource assigned to the LOE is not the same as the resource assigned to the other activities.

Since the manhours on an LOE could increase due to leveling, you will want to analyze your LOEs after leveling to ensure the increase in manhours is justified. An extreme increase may not be feasible. If so, you could change the LOE to Fixed Duration & Units before leveling to lock the total hours down. Keep in mind that the Units/Time will change instead when the duration changes.

If you’re a current Primavera user and would like advanced training on managing resource allocation and leveling, visit AdvancedP6Training and view TEPCO’s 1022 Primavera Advanced course. You may also contact TEPCO’s training department at (832) 514-4482.