Jun 11, 2025 | Announcement, General

Transforming Project Success: How Tepco Solutions Redefines Project Controls

In today’s complex industrial landscape, project managers face an ongoing challenge: how do you navigate intricate processes while maintaining clarity, control, and profitability? The answer lies in integrated project control solutions that don’t just manage complexity—they simplify it.

The Challenge of Modern Project Management

Complex projects often fail not due to technical issues, but because of poor planning, unrealistic schedules, and inadequate cost control. Traditional approaches leave teams struggling with fragmented systems, unclear processes, and data that doesn’t provide actionable insights. The result? Projects that run over budget, behind schedule, and fail to deliver maximum return on investment.

A Comprehensive Approach to Project Controls

Tepco Solutions has developed an integrated methodology that addresses these challenges head-on. Their approach centers on providing clients with the clarity needed to make sound business decisions through:

Foundation Elements:

- Accurate, realistic planning and scheduling

- Credible budget development and management

- Structured change and risk management processes

- Fully customized solutions tailored to specific needs

Operational Excellence:

- Comprehensive cost control systems

- Streamlined processes that eliminate inefficiencies

- Maximum return on asset optimization

The Tepco Solutions Framework

1. Diagnostic Assessment

Every successful project begins with understanding current state. Tepco’s diagnostic process evaluates existing systems and processes to identify gaps and deficiencies, creating a roadmap for improvement.

2. Strategic Implementation

Based on assessment findings, the team deploys intuitive solutions and procedures designed specifically for each client’s unique environment and challenges.

3. Knowledge Transfer

Customized training ensures teams can effectively utilize new integrated processes, while comprehensive documentation provides ongoing reference materials for all users.

4. Resource Solutions

Access to experienced, qualified project controls professionals who can work onsite or remotely, providing specialized expertise exactly when and where it’s needed.

5. Continuous Support

24/7 help desk support ensures technical needs are addressed immediately, while ongoing data integrity maintenance keeps information viable and accurate.

6. Future-Focused Improvement

Continuous monitoring of industry trends and emerging technologies keeps solutions at the cutting edge of project controls innovation.

Specialized Services That Drive Results

Advanced Training Programs

With over a century of combined industry experience, Tepco’s training programs offer something rare: real-world wisdom applied to practical challenges. Their experienced instructors provide hands-on learning that enhances retention and enables immediate application to specific project needs.

Training options include:

- In-person intensive workshops

- Live instructor-led sessions

- Online self-paced modules

- Primavera P6 specialty courses

Primavera P6 Excellence

As P6 implementation specialists, Tepco Solutions provides comprehensive services including:

- Application administration for cloud or on-premise environments

- 24/7 technical support and troubleshooting

- Standard operating procedure development

- Complete software implementation and upgrade assistance

Schedule Development and Management

Remote and onsite scheduling services help clients avoid traditional onboarding costs while ensuring daily interaction when situations demand it. The team’s extensive cross-industry knowledge enables rapid development of credible schedules that engage stakeholders effectively.

Tepco Solutions specialists have successfully developed and maintained CPM schedules for numerous clients onsite and remotely through online meetings and web-based scheduling software. Their extensive knowledge across the industry allows them to build credible schedules quickly, working with input from client teams.

Risk Management and Assessment

Every project faces uncertainties. Tepco’s risk management approach includes:

- Schedule Constructability Reviews to ensure compliance with project scope

- Schedule Quality Reviews for inherited or poorly prepared schedules

- Risk Workshops to identify hazards affecting cost and schedule

- Forensic Schedule Analysis for projects facing major delays or claims

Technology-Driven Solutions

Power BI Reporting Integration

Tepco’s dedicated reporting resources focus on consolidation through Power BI, creating unified dashboards that integrate schedule, cost, risk, and change management data from multiple applications.

WorkPAK Planning Solution

This innovative application improves efficiency across all project controls aspects, providing a warehouse of past tasks for future reference and enabling rapid duplication of entire events.

Advanced Droning and Scanning Services

State-of-the-art technology delivers:

- Immersive 3D walk-throughs of project sites

- High-resolution aerial imagery for detailed analysis

- Remote viewing capabilities that reduce travel costs

- Data-driven insights that directly correlate with project management systems

Comprehensive Resource Solutions

Tepco Solutions provides qualified professionals across all project control disciplines:

- Project and Turnaround Managers

- Project Controls Managers and Estimators

- Planners, Schedulers, and Cost Engineers

- Contract Administrators and Material Managers

- Field Planners and Procurement Specialists

The Bottom Line

In an industry where margins matter and schedules are critical, Tepco Solutions offers more than services—they provide a strategic advantage. By combining decades of experience with cutting-edge technology and proven methodologies, they enable organizations to achieve what many consider the holy grail of project management: projects completed on time, on budget, and with maximum return on investment.

Whether you’re managing a complex industrial turnaround, implementing new software systems, or seeking to optimize existing project controls processes, the key to success lies in having the right combination of expertise, technology, and support. Tepco Solutions delivers all three, wrapped in a commitment to continuous improvement and client success.

Ready to transform your project controls approach? The complexity doesn’t have to be complicated when you have the right partner guiding the way.

Jun 15, 2020 | Documentation, Highlights

This article is written for schedulers who are using the Resource Assignment functionality in Primavera P6 and performing the following functions as schedules are developed:

- Adding multiple resources to the same activity.

- Assigning different companies to resources on an activity.

- Utilizing resource codes to distinguish attributes such as direct and indirect labor.

- Utilizing a change management process to control added, modified, or deleted work.

- Using a dual baseline management process including:

- Original Baseline – is set and never modified

- Working Baseline – is updated based on ‘approved’ change orders

- Reporting earned and planned value at the resource assignment level.

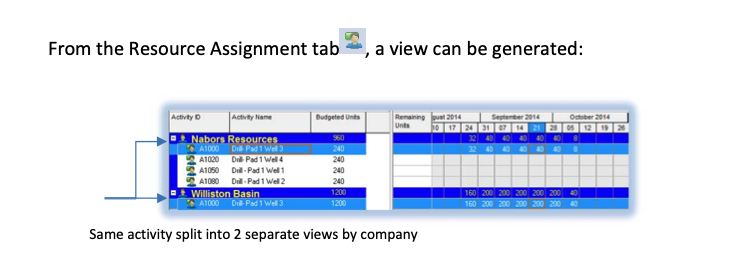

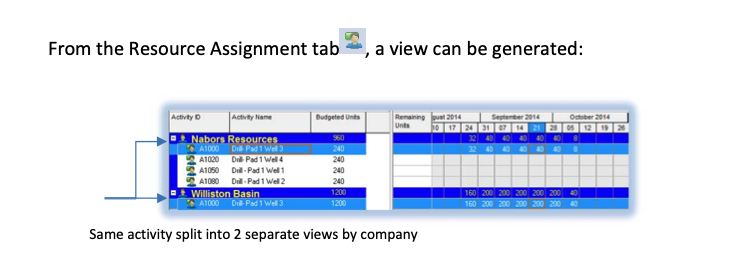

One of the key benefits of using Primavera P6 is the ability to add two or more resources that perform work for two or more companies and then have the ability to look at the resource budgeted hours or cost at a company or resource level in a consolidated resource assignment view. Another added option is the summary resource reporting.

Note: Given the reporting capability defined above; company management and cost controllers will recognize and realize the benefit of the reports. In order to make the reports usable, however, cost accounts and a rigid company/resource reporting structure needs to be in place.

However, after stating the added benefit of resource budget reporting, Primavera P6 does not have the capability to further breakdown and report either earned or planned value at the resource level. All earned value calculations are performed and reported at a level no lower than the activity. One would think that given the ability to split a single activity at the resource assignment would have also led to the ability to report either earned or planned value at the resource assignment level. This deficiency has led schedulers to either perform manually intensive workarounds or simply assign one resource to one activity giving up one of the key benefits of Primavera P6.

Keep in mind however that in order to report any meaningful planned or earned values in Primavera P6, baseline management must take place to calculate Schedule Performance Index

the key benefits of using Primavera P6 is the ability to add two or more resources that (SPI). This should be done using both an Original baseline and a Working baseline which is used to manage approved changes.

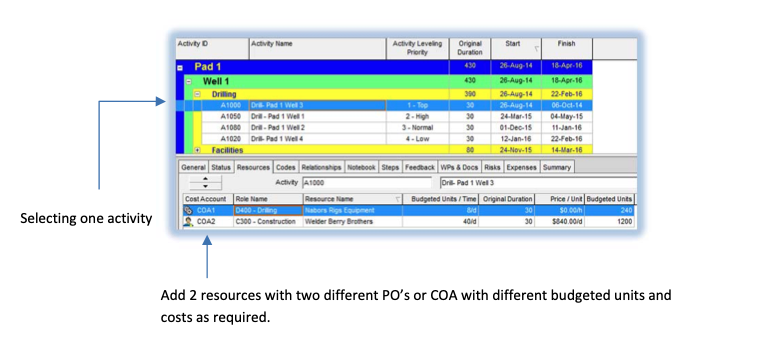

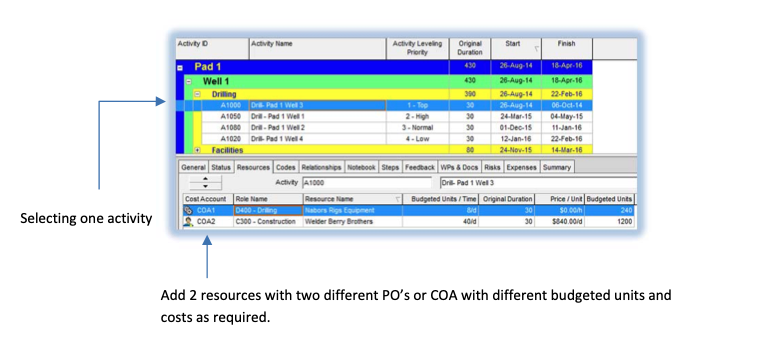

As has been stated; as an activity is added to a schedule, multiple resources can be assigned to that activity as shown below:

An added benefit of the multi-company/multi-resource capability in Primavera P6 is the ability to map the Cost Breakdown Structure (CBS) to the resource performing that work. Even without storing actual cost in Primavera P6, performance could be reported back to the cost controller to help in the tracking of cost. This is generally accomplished by utilizing fields in Primavera P6 such as:

- Cost Code or Work Order

- Company

- Total Budgeted Units (Direct and Indirect)

- Earned Labor Units

- Planned Labor Units BL (Primary or Original BL)

- Planned Labor Units BL1 (Primary or Original BL)

- Remaining Labor Units

The benefit does come with limitations. The fields noted above are not available at all levels in Primavera P6. Some are available at the activity level only while others are available at the resource level and viewable in the resource assignments view. Herein lies the issue; if there is one activity and two or more resources working for two or more different companies, you cannot report earned or planned values for those companies without going through multiple, time consuming steps. This is one of the main reasons so many schedulers today are seen moving data from Primavera to Excel during a projects lifecycle and as project change occurs.

The views shown below show the disconnect between the resource and activity level in Primavera P6.

Resource Assignments View – note there isn’t a field available for planned or earned units.

Activities View – several available options, but no ability to group by resource assignment in order to split units, cost account, company, or resource code.

The remainder of this paper describes the process to obtain the data, maintain the changes, and retain accurate variance and budgeted units reporting utilizing data derived from Primavera P6.

Step One:

Add two baselines – once data has been time distributed, reviewed and approved, and the

budgeted units are in alignment with the estimate.

- Original Baseline – add this baseline and assign it as the Primary Baseline in Primavera P6. This baseline will not be updated again.

- Working Baseline – add this baseline and assign it as the Project Baseline in Primavera P6. This baseline will be maintained and used to capture approved changes.

From the resource assignment screen you can obtain the budgeted units by copying and pasting or generating a report (this practice is recommended to minimize copy/paste errors) in a time- distributed format. This report will be summarized to the company (generally) and used as the Original Baseline hours in Excel.

If using the “copy/paste” function be aware that your time distribution will be limited to a 24 hour midnight to midnight “shift.” If reports are based on a custom shift calendar you must generate a report to reflect this.

The original hours for the first plot line are now available for Excel graph.

Step Two:

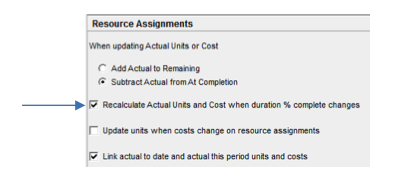

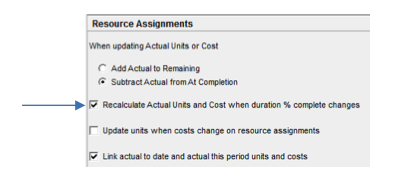

Set actuals in Primavera P6 as the earned so the actual and earned are equal values.

Since there isn’t the capability in the resource assignments view to see earned units or cost, enabling this option gives the scheduler earned hours based on progress % complete.

The same report as above can be built or copied/pasted, then modified to remove the budgeted units and replaced with the actual (earned) units. This will become the earned units which will be reported each period and plotted. This report is generally easy to maintain and run at the end of each progress update to be provided to the cost controllers.

The earned units for the second plot line are now available for Excel graph.

Step Three:

Changes occur and approvals take place (additions or deletions) and they must be:

- Updated in your current project file – with current Data Date

- Updated in the Working Baseline – retaining Original Baseline Data Date

In order to get the Working Baseline data into the Excel graph you must restore the WorkingBaseline from the project schedule.Note: The Update Baseline function in Primavera P6 has been prone to errors and if used will not correctly report milestone variances. The Working Baseline must be time distributed (based on the original Data Date – Do Not Advance the Data Date) to see the new end date based on the approved changes. The Update Baseline function does not work in this manner in Primavera P6.Once the Working Baseline is restored as its own project file, you can now make the approved changes. Most schedulers will open the current project and the Working Baseline at the same time and copy from the current project and paste into the Working Baseline when adding new activities. Note that logic ties must be made exactly the same as they were in the current project file.From the Working Baseline file, and after changes are made, navigate to the resource assignment screen. Utilizing the ‘Budgeted Units’, run the same report built in Step One of this process and plot the Working Baseline in Excel.The planned units for the third plot line are now available for the Excel graph. This process gives you the ability to report the following data utilizing:

- Multiple resources assigned to the same activity.

- Resources allocated to different companies and assigned to a given activity.

- Resource codes to distinguish between attributes such as direct and indirect labor.

- A change management process to control added, modified, or deleted work.

- A two part baseline process which includes:

- Original Baseline – added and never adjusted (the starting point)

- Working Baseline – added and updated based on ‘approved’ change orders

- Reporting of earned and planned value at the resource assignment level.